| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

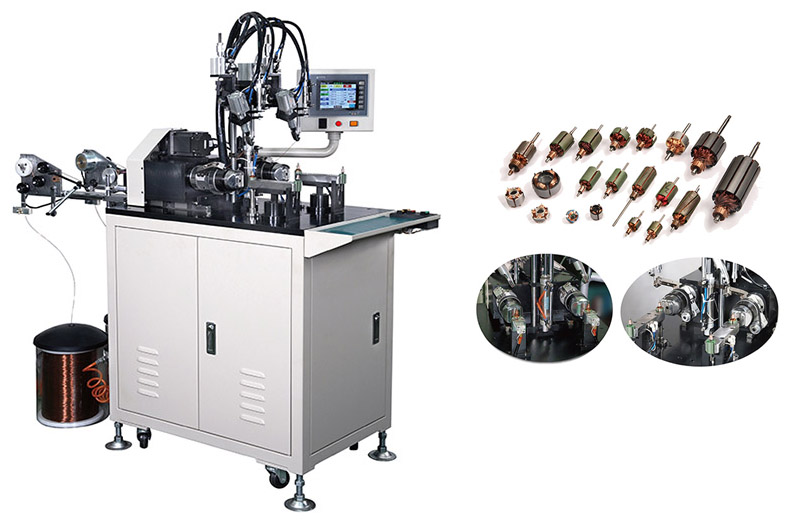

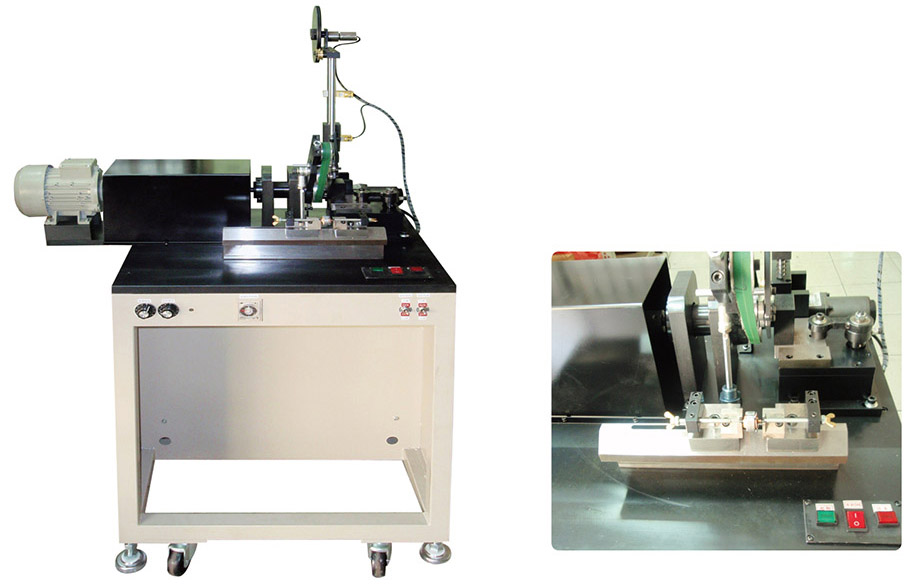

This double-shaft single flying fork rotor winding machine is ideal for coils in micro motors, appliances, power tools, and motorcycle motors. With a bi-directional auto turntable and touch interface, it offers high efficiency and stable quality. Mold changes are quick, wire cutting is neat with no waste, and wires are consistently aligned. Automatic trimming and breakage handling reduce labor, cut costs, boost output, and save enameled wire and time¡Xmaking it a dependable solution. ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

|

Double Shaft Single Flying Fork Rotor Winding Machine (Protective Cover) | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

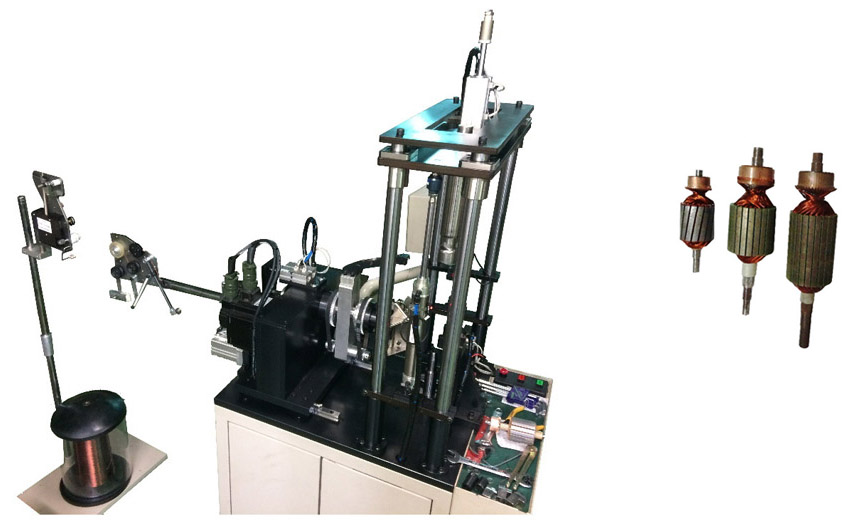

This double-shaft single flying fork rotor winding machine with a protective cover is suitable for coils in micro motors, appliances, power tools, and motorcycle motors. It features a bi-directional auto turntable and touch interface for efficient, stable operation. Quick mold changes, precise wire cutting with no waste, and neat alignment ensure quality. With auto trimming, break handling, and enhanced safety, it saves labor and materials¡Xmaking it a reliable, high-performance solution. ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@

| |||||||||||||||||||||||||||||||||||||||||||||

| Four Axis Single Flying Fork Rotor Winding Machine | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

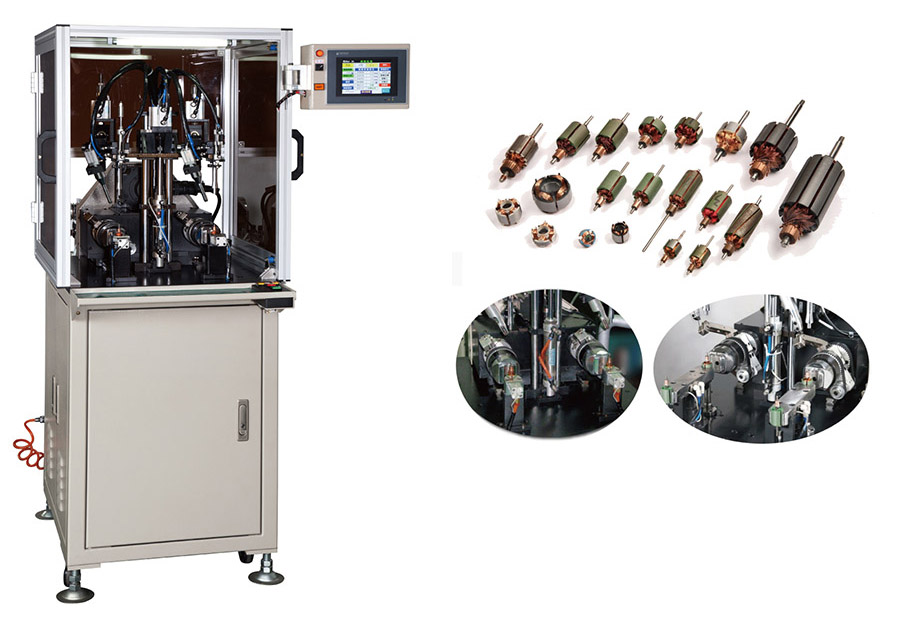

The four-axis single flying fork rotor winding machine is ideal for micro motors, appliances, power tools, and motorcycle motors. With a bi-directional turntable and touch interface, it ensures easy operation and stable efficiency. It offers quick mold changes, neat wire cutting, precise alignment, and automatic trimming¡Xsaving labor and costs, making it a reliable, high-performance solution. ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@

¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| Vertical Rotor Winding Machine | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

This vertical rotor winding machine is suitable for coils in micro motors, household appliances, power tools, and motorcycle motors. Featuring manual loading and unloading, it offers stable performance and easy operation, making it a practical and reliable solution. ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| Rotor Three Pole Synchronous Winding Machine | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

This rotor three-pole synchronous winding machine is designed for winding three-pole motors before commutator installation. It features synchronous winding with stable performance and easy operation, making it an efficient winding solution. ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

¡@

| |||||||||||||||||||||||||||||||||||||||||||||

¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| Motor Coil Winding Machine | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

This motor coil winding machine is suitable for 3-pole and 5-pole motor winding. It features simple operation, low noise, stable performance, and high output¡Xmaking it an ideal choice for efficient, quality production. ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

This machine is designed for precision turning of motor commutators used in automobiles, locomotives, power tools, and household appliances. It features AC servo motor drive, precision ball screws, and linear rails, all controlled by a PLC system for stable and accurate operation. The diamond V-shaped seat pillar reduces wear and increases machine durability. Both X and Y axes use servo motors and precision screws to ensure turning accuracy. The system includes a user-friendly HMI touch screen for easy operation. The machine calculates cutter depth and knife count per mm based on motor speed. Teaching-mode parameter setting and servo jog function allow quick adjustments. It supports automatic, manual, and single-step modes, with flexible multi-pass turning settings. ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

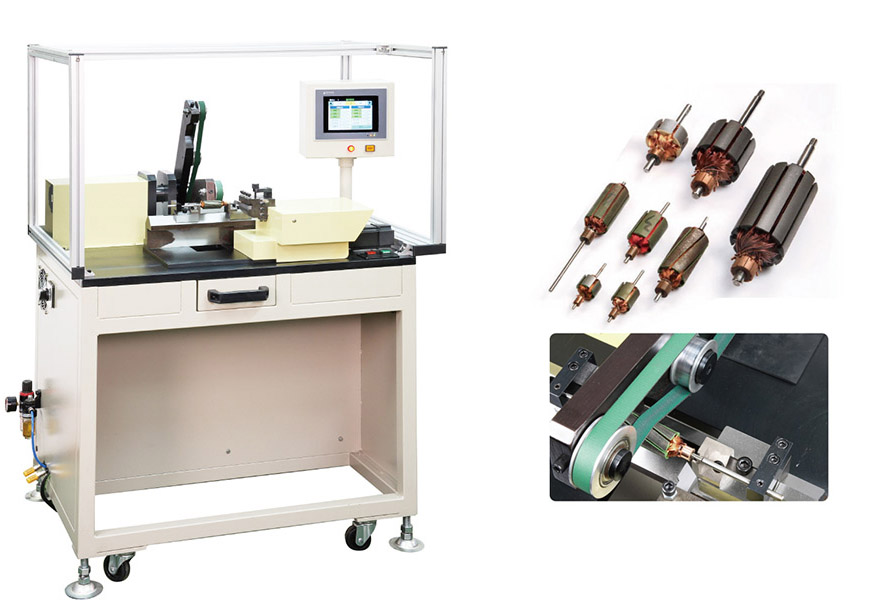

This machine is designed for precision grinding of motor commutator outer surfaces in automobiles, locomotives, power tools, and household appliances. It offers stable performance, low noise, easy operation, and high productivity¡Xideal for mass production. ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| ¡@ | |||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||