Grinder

The high-speed grinder

attachment can be used with most lathes or grinding machines. The

grinding wheel is mounted on a high-speed spindle for smooth operation

and precise surface finishing. |

|

|

Model |

PHT - 91 |

PHT - 92 |

PHT - 93 |

|

Max. working length & dia depends on lathe used. |

|

Wheel size |

10¡¨ x 1.25¡¨ |

12¡¨ x 1.5¡¨ |

16¡¨ x 1.5¡¨ |

|

Speed RPM |

2300 |

1900 |

1450 |

|

Motor |

3 HP |

5 HP |

7.5 HP |

¡@

¡@

¡@ |

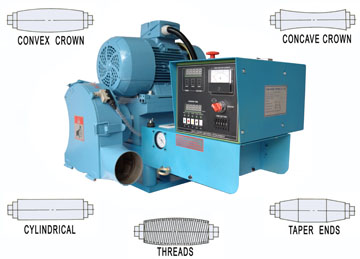

Crown Grinder

for Roll

|

This grinder is designed for grinding rubber and PU rolls. It can be

mounted on any existing lathe without modification. It has the

capability to grind sine, parabolic, and other convex or concave crown

profiles. |  |  | ¡@ | ¡@

|

Model |

PHT - 94 |

PHT - 95 |

PHT - 96 |

|

Max. working length & dia depends on lathe used. |

|

Wheel size |

10¡¨ x 1.25¡¨ |

12¡¨ x 1.5¡¨ |

16¡¨ x 1.5¡¨ |

|

Speed RPM |

2300 |

1900 |

1450 |

|

Read out |

0.01 mm / 0.0005¡¨ |

|

Crown range |

Height 0.02 - 8.00 mm (D-d) |

|

Motor |

3 HP |

5 HP |

7.5 HP |

¡@ | |

| ¡@ | ¡@ |

Carbide Wheels |

This Rubberhog carbide wheel is designed for high-speed use and works with

various non-metallic materials. It allows for one-pass grinding to the

desired diameter, saving up to 75% of processing time. It also helps reduce

smoke and scorch marks when cutting rubber or PU. With high speed, low

vibration, and strong power output, it offers excellent performance and

finish quality. | | ¡@ | ¡@ |

| |

Size | 10" | 12" | O.D x I.D. | 10" x 4" | 12" x 4" | |

Thickness | 1 1/4" | |

Max speed RPM | 8000 | 6000 | |

Weight |

9 kgs |

13 kgs |

|

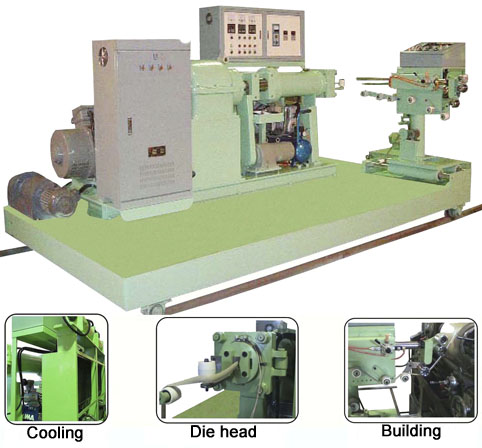

| Rubber

Roll Strip Building Machine |  | |

This machine is used for building medium to large-sized rubber rollers,

often in industries such as steel, paper, and plywood. It consists of a

rubber extruder and a user-friendly applicator system mounted on a traveling

platform that moves along the roller's X-axis and Z-axis. The system

includes a stationary spin station. | ¡@

|

|

Model |

PHT - 1270 |

|

Max & min roll

diameter |

1270 / 25 mm

( Depend on spin station and option for the extruder ) |

|

Cover thickness range |

10 mm per pass |

|

Diameter

of screw |

£X 75 mm |

|

L/D ratio of screw & speed |

12:1 / max. 40 RPM |

|

Feed roller reducer motor |

DC 1 HP |

|

Full auto temp. & cooling control system |

3 positions / 2 positions |

|

Cooling motor |

AC 1 HP x 2 units |

|

Air

pressure |

2 HP max. 5.0 kgf / cm |

|

Gear box motor |

DC 40 HP |

|

Operating roller centerline height |

140 cm |

|

Traveling platform wheel size

diameter |

£X 125 mm x W 55 mm |

|

Track size |

W 50 mm

( Floor track, cableway & cabling option for the extruder ) |

|

Traveling platform motor |

AC 2 HP ( Inverter ) |

|

Machine dimensions & net weight |

L 400 x W 230 x H 230 cm / 6000 kgs |

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@ |

|

¡@

Rubber Roll Production Flow Chart

|