| B/C

Green Tire Pre-forming Machine |

| °@ |

|

The B/C green tire pre-forming machine shapes the tire uniformly before

building. It auto-adjusts pressure and form, supports multiple sizes,

prevents wrinkles, and ensures smooth, consistent results for further

processing.

|

|

| °@ | °@ Model | PHT - 012 | | Tire size | 12, 14, 16, 18, 20, 22, 24, 26, 27~ 28°® | Air pressure | 1.5 ~ 4.5 kg / cm |

|

|

|

| Tire

Curing Press |

PHT hydraulic tire curing presses were developed to meet tire

manufacturers°¶ demand for improved tire uniformity and reduced energy

consumption. They offer high efficiency and stable performance.

|

| | |

|  |

|

°@ |

|

| °@ |

Model | PHT - 28 | PHT - 19 | PHT - 20 | Vulcanized tire size | B/C | B/C, M/C | B/C, I/D | No. of daylight | 6 ~ 7 | 5 | Platen outside dia (mm) | 918 | 750 | 560 | Mold thickness (mm) | 100 ~ 120 | 60 ~ 100 | 60 ~ 200 | Clamping force (tons) | 75 | 48 | Hydraulic working pressure | 130 kg / cm | | Steam platen pressure | 8 kg / cm | Curing system | Steam |

|

|

|

Bolt & Nut

°@ |

|

The bolt and nut are used to lock the mold in the tire curing press,

ensuring stable fixation under high pressure and temperature for safe

and reliable curing. |

|

|

°@ |

|

°@ |

| °@ |

°@

Bolt size |

3/4" x 5", 3/4" x 7"

5/8°® x 5°®, 5/8°® x 7°® | |

Nut size |

3/4°®, 5/8°® |

°@ |

Bolt

& Nut Bolt

& Nut°@ |

| BOM

Tire Curing Press |

°@

PHT hydraulic tire curing presses were developed to meet motorcycle tire

manufacturers°¶ demand for better tire uniformity and lower energy

consumption. They offer high efficiency, low energy usage, and

consistent quality.

°@ |

|

| |

| |

°@ | Model | PHT - 55

- 3 | PHT - 56

- 3 | PHT - 57 | PHT - 27 | Vulcanized tire size | Bicycle tire 12-1/2°® ~ 20°® | Bicycle tire 20°® ~ 28°® | Motorcycle tire 350 - 14°® ~ 21°® | L/T 500 -12°® M/C tire 14°® ~ 21°® | No. of cavity |

3 |

3 | 3 | 2 | Max. clamping force |

74 tons | 135 tons | Working clamping force |

58 tons | 85 tons | Hydraulic working pressure | 120 kg / cm2 | Oil cylinder size | £X250 °— 1350st | £X300 °— 1350st | £X356 °— 1740st | £X300 °— 1440st |

Platen outside dia. | £X 700 mm | £X 910 mm | £X 915 mm |

Platen Inside dia. |

£X 155 mm |

£X 323 mm |

£X 296 mm | Mold thickness | 100 - 120 mm | 130 - 200 mm | 80 - 250 mm | Max. opening space | 450 mm | 580 mm | 720 mm | Green tire height | Max.

150 - 160 mm | Max. 240 mm | Max. 350 mm | Mold opening /closing time |

15 sec. |

12 sec. | 20 sec. | Inside platen steam pressure | 8 kg / cm | Internal pressure | 18 kg / cm | 20 kg / cm | Air pressure | 7 kg / cm | Vacuum | About 100 mm Hg | Curing system | Steam & Hot water or Steam & Nitrogen. | Overall dimension mm | L 974 x W 900 x H

2941 | L 1184 x W 900 x H

2946 | L 1194 x W 1000 x H

3364 | L 1194 x W 1000 x H 2830 | Mc weight | 3000 kgs | 3890 kgs | 4000 kgs | 4600 kgs |

|

| °@ | | BOM

Tire Curing Press | | °@ |  |  |

| °@ | | °@ | °@ | | Model | PHT-32 | PHT-36 | PHT-42 | PHT-46 | PHT-67 | PHT-68 | PHT-69 | | Vulcanized tire size | I/D, M/C, ATV | I/D, M/C, ATV | M/C,I/D, ATV,L/T | I/D,ATV,L/T | I/D,ATV | I/D, ATV, M/C | I/D, ATV, M/C | No. of cavity | 2 | 4 | Max. clamping force | 103 tons | 129 tons | 148 tons | 168 tons | 53 tons | 80 tons | 103 tons | | Platen outside dia. | £X 815 mm | £X 915 mm | £X 1067 mm | £X 1167 mm | £X 600 mm | £X 710 mm | £X 760 mm | | Mold thickness mm | 90 ~ 200 | 150 ~ 350 | 150 ~ 400 | 100 ~ 300 | 150 ~ 350 | Inside platen steam pressure | 8 kg / cm | | Internal pressure | 20 kg / cm | | Air pressure | 7 kg / cm | | Vacuum | About 100 mm Hg | Curing system | High temperature hot water and steam |

|

| | Post

Cure Inflator ( PCI ) | | °@ | |

The Post Cure Inflator (PCI) features simple operation and high

efficiency while saving space. Its inflation and shaping functions

effectively enhance the appearance and roundness of tires.

|

|

|  |  |

| | °@ | °@ | | Model | PHT - 81 | PHT - 82 | PHT - 83 | | Tire size | M/C 10°® - 21°® | I/D 6°® - 12°® | I/D,ATV L/T 12°® - 16°® | | Inflation type | Horizontal | | Air pressure | 3 - 7 kg / cm |

|

|

|

|

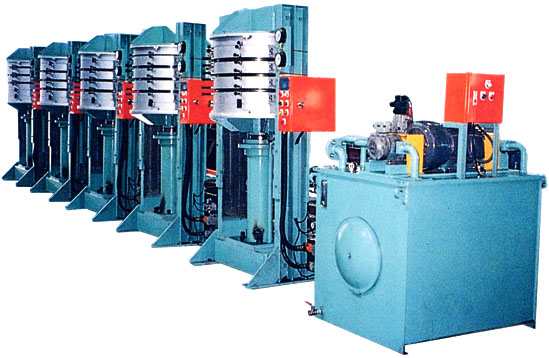

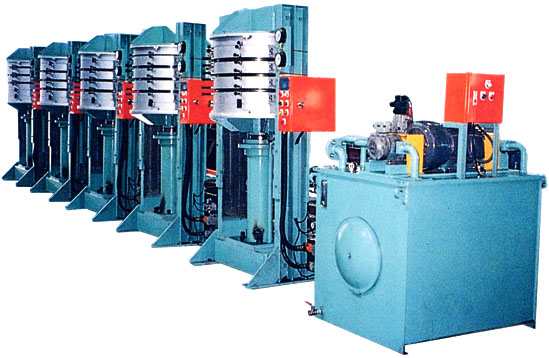

Vacuum

Pump System for BOM Press |

|

|

The Vacuum Pump System for BOM Press is designed to remove air from the mold

during the curing process, effectively preventing air bubbles and ensuring

proper bonding and shaping of the rubber material, which improves both the

appearance and structural stability of the final product.

°@ |

|

|

|

Model |

PHT - 285 |

|

Tank volume |

1000 liter x 2 pcs |

|

Vacuum pump |

15 HP x 2 |

|

Vacuum pump capacity |

4.6 m3/min at 110 Tor / 650mmHG |

|

Vacuum pressure |

Max. 60 Tor / 700 mmHG |

|

| °@

|

|