Rubber

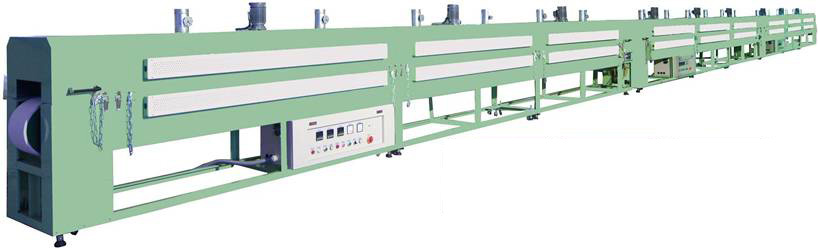

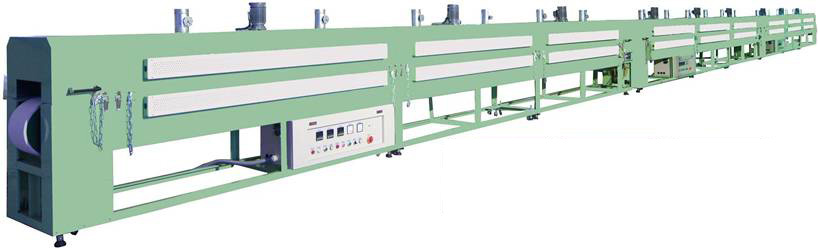

Continuous Vulcanizing Line

¡@

|

|

The PHT continuous vulcanizing line is designed for the production of rubber

sponges, tubes, rods, O-rings, profiles, door glass guide channels,

windscreen strips, and more. It offers high-speed production, excellent

performance, fully automated temperature control, simplified operation,

labor savings, and consistent product quality.

Model | PHT - 023 | Interior & Exterior size | W 380 x H 120 mm / W 820 x H 650 mm | Conveyor size | W 15 x L 1870 cm x 3 sets | Air exhaust | 18 sets | Air blower motor | AC 1/4 HP x 9 sets | Main motor | AC 1 HP x 3 sets ( Inverter ) | Temperature controller | SCR system with PID temperature regulator x 3 sets | Temperature | Max. 250 ¢XC / 27 KW ( 54 units IR heater ) | Line speed | 7- 21 m / min | Machine dimensions | L 27120 x W 820 x H 1400 mm |

¡@

¡@

Rubber

Profile Production Flow Chart

¡@

4 -

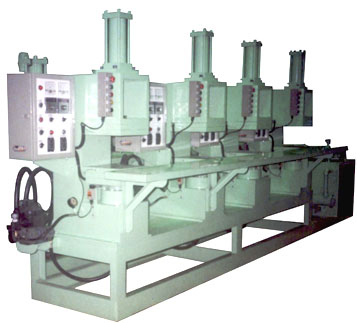

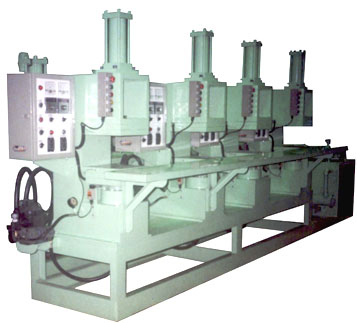

Station Injection Transfer Press |

This machine is designed for injection transfer molding of corners on rubber

sponges, profiles, door weatherstrips, windscreens, trunk seals, and similar

products. |

|

| Model | PHT - 2600 | Material capacity | 175 gram | Daylight dimension | W 300 mm x D 280 mm x 1 | Upper hydraulic cylinder | £X 100 mm x 150 ST mm | Normal working force | 12 tons / 150 kg/cm | Main hydraulic cylinder | £X 120 mm x 200 ST mm | Normal working force | 17 tons / 150 kg cm | Curing system | Electric | Motor | 7 1/2 HP x 6 P |

¡@ |

|

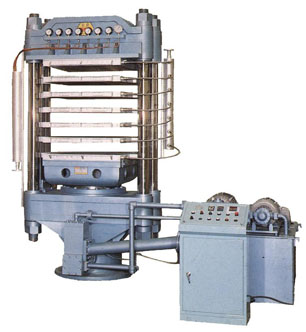

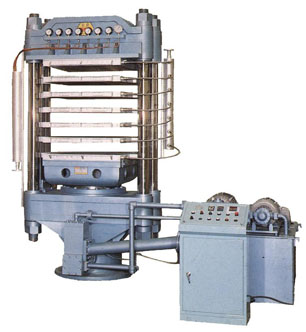

Hydraulic

Foam Molding Machine

¡@

This machine is suitable for producing EVA or PVC forming plates,

beach shoes, foam and sponge rubber soles, and other industrial

rubber products.

After mixing, materials like EVA, PVC, rubber, or PE are cured and

molded into foam sheets through high-pressure compression. The

machine rises quickly and steadily, equipped with a fast-release oil

valve for rapid descending and adjustable speed for consistent

quality.

It also features auto pressure compensation, adjustable bumping

pressure and timing, and a specialized heating circuit for even heat

distribution. The centralized circuit design makes operation and

maintenance simple and efficient. |

|

¡@

¡@

¡@

Model | PHT - 224 | PHT - 230 | PHT - 236 | Piston | 24¡¨ | 30¡¨ | 36¡¨ | Hot plate (cm) | 100 x 100 | 120 x 150 | 140 x 160 | Distance | 120 mm | 150 mm | 150 mm | Step | 6 | 6 | 6 |

¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@

¡@

¡@ ¡@ ¡@ |

|