|

Cold Feed

Type

Extruders |

|

|

|

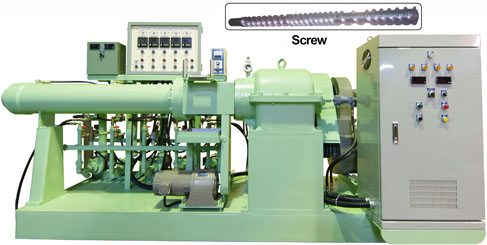

These machines are cold feed extruders equipped with specially designed

screws and machine structures optimized for cold feed operation. Each

unit includes an extruder, a temperature control unit, a drive motor,

and a control panel. Rubber in the form of tapes, pellets, or slabs can

be fed directly into the extruder without preheating. |

| ¡@

¡@

|

|

Model |

PHT - 35 |

PHT - 75 |

PHT - 90 |

PHT - 120 |

PHT - 150 |

|

Dia. of

screw (mm) |

£X 35 |

£X 75 |

£X 90 |

£X 120 |

£X 150 |

|

L/D ratio of

screw |

14 : 1 |

18 : 1 |

16 : 1 |

|

Feed roller

reducer motor |

DC 1/2 HP |

DC 1 HP |

DC 2 HP |

DC 3 HP |

|

Full auto

temp. & cooling control system |

3 positions |

5 positions |

|

Cooling

motor (AC) |

1 HP x 3 units |

1 HP x

5 units |

|

Motor (DC

HP) |

10 |

50 |

60 |

100 |

125 |

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@ |

|

¡@

Silicone Rubber Extruder

¡@

The PHT

high-performance silicone rubber extruder is designed for

extruding slabs, flexible round cords, square cords, tubes,

and other custom shapes with precision.

|

Model |

PHT - 75 S |

PHT - 90 S |

|

Dia. of screw |

£X 75 mm |

£X 90 mm |

|

L/D ratio of screw |

12 : 1 |

|

Speed of motor ( RPM) |

0 ~ 1200 RPM |

|

Gear box motor |

DC 20 HP |

DC 25 HP |

|

Material feeding roller motor |

DC 1/2 HP |

DC 1 HP |

|

Capacity ( kgs/ Hr ) |

300 ¡V 400 |

400 ¡V 500 |

|

Chiller capacity |

3 M/T |

|

Temperature of ice water |

0¢XC ~ 20¢XC |

|

Motor |

3 HP |

|

Pump motor |

1/2 HP |

|

Full auto cooling control system |

|

Accessories : Inner tube head 1

set |

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@ |

¡@ ¡@ ¡@

¡@ ¡@ |

|

|

Model |

PHT - 75 H |

|

Dia. of screw |

£X 75 mm |

|

L/D ratio of screw |

12 : 1 |

|

Speed of motor |

0 ~ 1200 RPM |

|

Gear box motor |

DC 20 HP |

|

Ice water refrigerator capacity |

3 M/T |

|

Temperature of ice water |

0¢XC ~ 20¢XC |

|

Straight tube type vulcanize size |

L 1000 mm x ID 160 mm |

|

Temperature range |

0¢XC ~ 450¢XC / 30.6 KW, 2 step control |

|

Electric control |

Temperature, cooling display, etc |

| |

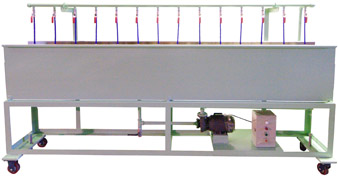

Cooling

Bath

The PHT high-performance cooling batch system is designed to cool

rubber profiles, strips, and similar materials. Other sizes are

available based on specific requirements |

¡@ |

|

|

¡@

|

Model |

PHT - 330 |

|

Bath size |

L 3 M x W 40 cm |

|

Pump motor |

1 HP |

¡@ |

|

|

|

|

¡@

¡@

¡@

¡@

¡@

The PHT chiller is designed to precisely control process

temperatures for rubber, plastics, die casting, chemical processing,

food production, and more. Custom specifications and sizes are

available upon request. |

|

|

Model |

PHT - 130 |

PHT - 155 |

PHT - 750 |

|

Water temp. |

5 ~ 25 ¢XC |

|

Kcal / H |

9375 |

15423 |

23866 |

|

Cap. Btu / H |

37200 |

61200 |

94700 |

|

Motor (HP) |

3 |

5 |

7.5 |

|

Pump motor |

1/2 HP |

1 HP |

2 HP |

|

Flow volume |

60 L / min |

120 L / min |

160 L / min |

¡@

¡@

¡@ |

¡@ |

The PHT belt-type

caterpillar haul-off machine features the latest drive technology

and is easy to maintain. It is suitable for continuous pulling of

various rubber and plastic profiles. | ¡@ | ¡@ |

|

¡@

|

Model |

PHT - 145 |

|

Height |

100 mm ( Adjustable ) |

|

Width |

250 mm |

|

Max. speed |

12 m |

|

Motor |

DC 2 HP |

|

Machine size |

L 130 x W 70 x H 150 cm |

|

|

|

|

|

|