|

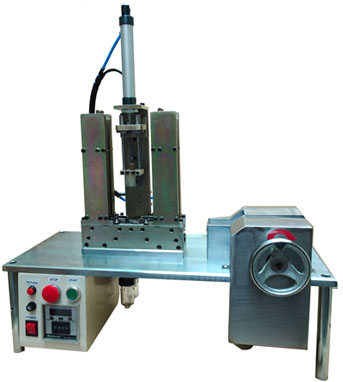

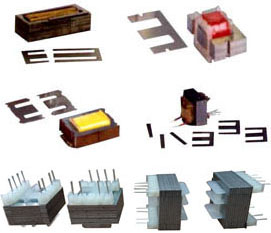

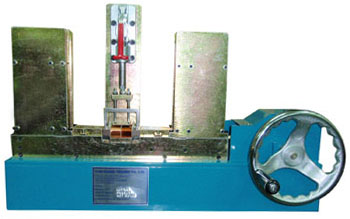

The core plate inserting machine is a specialized machine used in the

manufacturing of transformers. It can be divided into automatic and

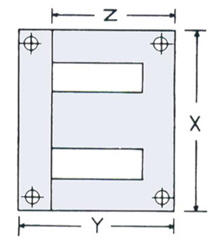

manual types. The automatic core inserting machine is designed to

automatically insert E-shaped and I-shaped silicon steel sheets into the

transformer coil. With accurate counting, fast speed, and high

efficiency, it is suitable for mass production of transformers,

significantly reducing production costs and saving labor.

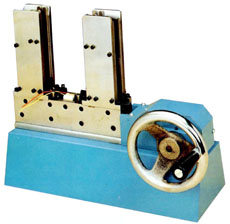

This machine is constructed from high-grade metal material and undergoes

special heat treatment to ensure excellent durability. It features a

robust and complete structure, low failure rate, easy operation, long

service life, and convenient part replacement. The operating speed can

be adjusted via an AC motor, and machines can be manufactured in any

required size.

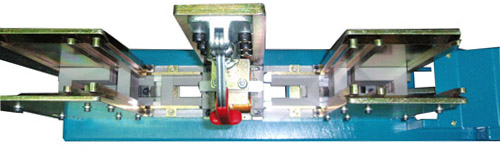

Storage boxes for E and I steel sheets are mounted on both sides of the

upper part of the machine. During operation, pressing the start switch

will cause the steel sheets to be fed one by one from the left and right

storage boxes into the transformer coil until the pre-set quantity is

reached. The machine is also equipped with a crimping device that

automatically clamps the bobbin during movement and releases it after

the insertion is complete, thereby enhancing work efficiency. The final

core sheet can also be inserted automatically. The machine begins

operation immediately upon pressing the start switch and stops instantly

when the stop switch is pressed. It also has an automatic stop function

in case a steel sheet gets jammed during insertion.

One machine is suitable for one type of iron core; however, the steel

sheet thickness can be adjusted freely between 0.5 mm and 0.35 mm

according to production needs. |