|

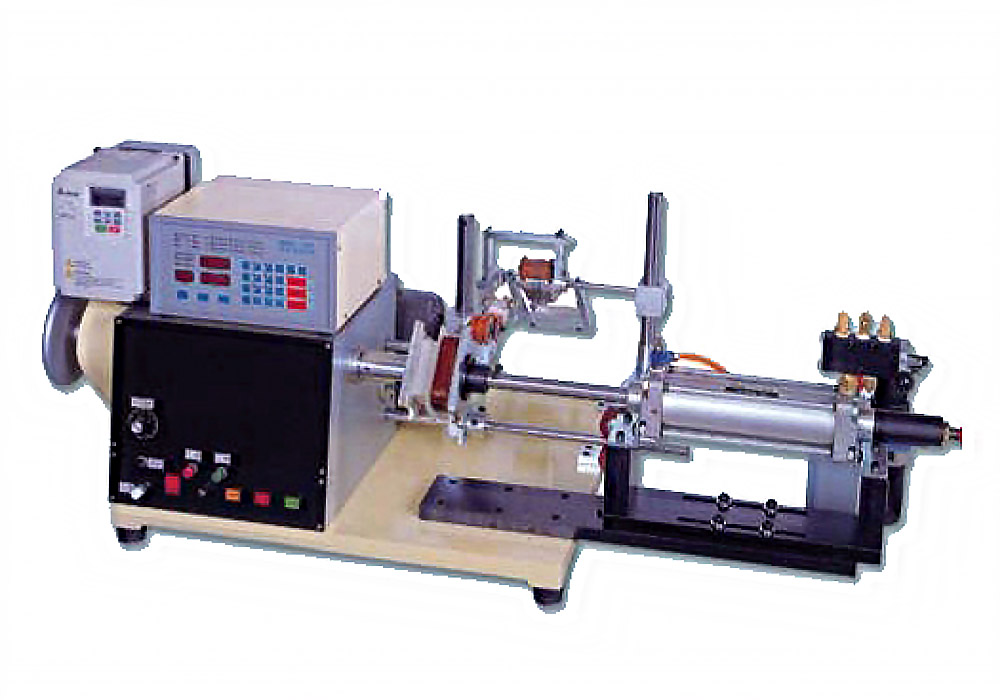

Four

Axis Automatic Winding Machine (Stranded Wire Frame )

|

|

|

|

The PHT-40-80AT is a newly developed four-axis automatic winding

machine. It features AC servo motor drive and CNC numerical control

with a user-friendly Windows-based interface. Offering excellent

performance and ease of operation, it supports quick fixture

changes, accurate spindle positioning, and multiple foot angle

settings (0 and 90 degrees). Its compact structure and intuitive

programming make it easy to operate, maintain, and highly reliable

for efficient production. |

|

|

|

|

|

|

|

Model |

PHT-40-80AT |

|

Spindle

speed |

Max 9,000 rpm, can be forward and reverse |

|

Number of spindles

|

4 axis |

|

Spindle pitch

|

80 mm |

|

Applicable wire size

|

0.03 ~ 0.5 mm |

|

Movement of nozzle |

(X-axis) 90 mm, (Y-axis) 80 mm, (Z-axis) 50 mm |

|

Control system |

Windows environment operating system |

|

Program input method |

Teaching method input |

|

Number of program

pre-set |

1000 groups, the program can be transferred from the CF card to the

computer or transferred to the CF card by the computer |

|

Power

|

AC 220V 3Φ 50/60HZ 2KVA |

|

Air pressure |

4-6 kg/cm2 |

|

Machine dimensions |

1700(L) x 700(W) x 1500(H) mm |

|

Weight |

300 kgs |

|

Optional equipment |

Stranded wire frame device |

|

|

|

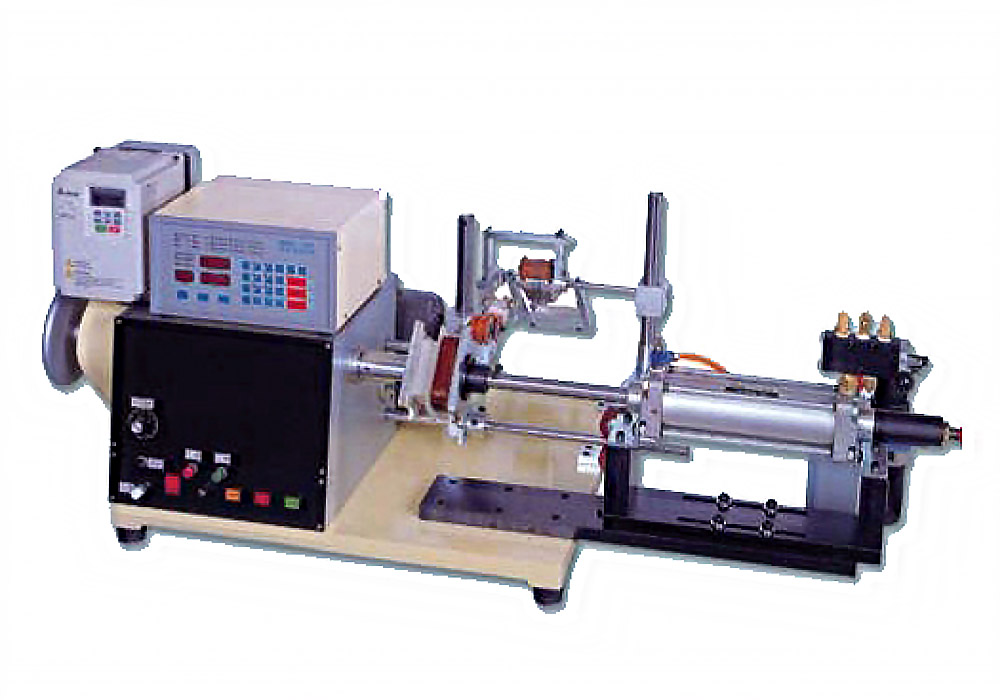

Four

Axis Automatic Winding Machine (Stranded Wire Frame ) Four

Axis Automatic Winding Machine (Stranded Wire Frame ) |

|

Six Axis Automatic Winding Machine

(Stranded Wire Frame )

|

|

|

|

The PHT-60-80AT is a newly developed six-axis automatic winding

machine, driven by AC servo motors and operated via a CNC numerical

controller with a Windows-based interface. It offers outstanding

performance and user-friendly operation. The machine features a

compact design for easy maintenance and high reliability, with

precise spindle positioning and support for multiple foot angles (0

and 90 degrees). Quick-change winding fixtures and an intuitive

programming interface further enhance efficiency and automation in

the production process. |

|

|

|

|

|

|

Model |

PHT-60-80AT |

Spindle speed |

Max 8,000 RPM, can be forward and reverse |

Number of spindles

|

6 axis |

Spindle pitch

|

80 mm |

Applicable wire size

|

0.03 ~ 0.5 mm |

Movement of nozzle |

(X-axis) 90 mm, (Y-axis) 80 mm, (Z-axis) 50 mm |

Control system |

Windows environment operating system |

Program input method |

Teaching method input |

Number of program pre-set

|

1000 groups, the program can be transferred from the CF card to the computer or transferred to the CF card by the computer |

Power

|

AC 220V 3Φ 50/60HZ 2KVA |

Air pressure |

4-6 kg/cm2 |

Machine dimensions |

1700(L) x

1400(W) x 1500(H) mm |

Weight |

400 kgs |

Optional equipment |

Bobbin fixed

press device,

Copper wire bubble

film peeling device,

Stranded wire frame

device

|

|

Six

Axis Automatic Winding Machine Six

Axis Automatic Winding Machine |

|

|

|

|

|

Six Axis

Automatic Winding Machine with Auto Loading / Unloading |

|

|

|

The PHT-60-80BT is a next-generation six-axis automatic winding

machine, equipped with automatic loading and unloading functions to

enhance production automation. It utilizes AC servo motor drive and

CNC numerical control with a Windows-based operating interface,

delivering superior performance and user-friendly operation.

Designed with a compact structure, it enables quick fixture changes,

precise spindle positioning, and supports multiple foot angles (0

and 90 degrees). The intuitive programming interface and simple

mechanical design ensure easy maintenance, low failure rate, and

reliable high-efficiency winding. |

|

|

|

|

|

|

Model |

PHT-60-80BT |

Spindle speed |

Max 8,000 RPM, can be forward and reverse |

Number of spindles

|

6 axis |

Spindle pitch |

80 mm |

Applicable wire size

|

0.03 ~ 0.35 mm |

Movement of nozzle |

(X-axis) 90 mm, (Y-axis) 80 mm, (Z-axis) 50 mm |

Control system |

Windows environment operating system |

Program input method |

Teaching method input |

Number of program pre-set |

1000 groups, the program

can be transferred from the CF card to the computer or transferred to

the CF card by the computer |

Power

|

AC 220V 3Φ 50/60HZ 2KVA |

Air pressure |

4-6 kg/cm2 |

Machine dimensions |

1700(L) x 1400(W) x 1500(H) mm |

Weight |

400 kgs |

|

Optional equipment |

Bobbin loading

and finished product unloading device

Copper wire binding

feet device |

|

|

|

Six

Axis Automatic Winding Machine with Auto Loading and Unloading Six

Axis Automatic Winding Machine with Auto Loading and Unloading |

|

|

|

|

|

CNC Servo Automatic Winding Machine |

|

|

|

This machine is suitable for coil and transformer winding

applications. Driven by servo motors, it ensures fast and stable

winding performance. Wire hanging and cutting are performed

manually, while the simple structure allows for easy operation, low

failure rate, and convenient maintenance—making it a practical and

efficient winding solution. |

|

|

|

|

|

Model |

PHT-1104-B |

|

Control method |

CNC 2-axis AC servo motor synchronization control |

|

Number of spindle |

3 pcs |

|

Winding speed |

Max 5000 RPM, can be forward and reverse |

|

Applicable wire diameter |

Max 2.0 Φ |

|

Coil diameter |

Max 280 Φ |

|

Coil width |

Max 200 mm |

|

Machine dimensions |

115(L) x 78(W) x144(H) cm |

|

Weight |

194 kgs |

|

|

|

|

|

|

Programmable Automatic Coil Winding Machine |

|

|

|

The M927G series is a high-performance coil winding machine,

designed for applications such as magnetic coils, oscillator coils,

relay coils, synchronous motor coils, telephone coils, and

fluorescent lamp ballasts. With speeds reaching up to 7000 RPM, it

offers exceptional production efficiency.

Equipped with a microprocessor, the machine controls wire guidance

precisely via a stepper motor-driven traverse shaft. Parameter

settings are user-friendly and displayed clearly on the control

panel. Ceramic guide rollers minimize heat buildup and protect

enameled wire. The system supports nine winding parameters and five

configurable options per step, allowing flexible multi-segment,

multi-speed operations. With memory capacity for storing up to 999

step sequences for over one year, the M927G is a powerful solution

for precision coil winding automation.

|

|

|

|

|

|

Model |

M927G2 |

M927G3 |

M927G4 |

|

Number of spindles |

2 |

3 |

4 |

|

Control method |

Microcomputer control |

|

Memory capacity |

999 segment winding information |

|

Spindle speed |

0 ~ 7000 R.P.M |

|

Wire diameter |

0.03 ~ 0.8 mm |

0.03 ~ 0.5 mm |

|

Coil outer diameter |

Max 100 mm |

|

Coil width |

0 ~ 100 mm |

|

Motor |

1/2 HP DC 1Φ |

|

Machine dimensions |

58 x 52 x 120 cm |

58 x 62 x 120 cm |

58 x 72 x 120 cm |

|

Weight |

48 kgs |

55 kgs |

63 kgs |

|

|

|

|

|

|

|

|

Model |

M927G1A |

M927G2A |

|

Number of spindles |

1 |

2 |

|

Control method |

Microcomputer control |

|

Memory capacity |

999 segment winding information |

|

Spindle speed |

0 ~ 3000 R.P.M |

|

Wire diameter |

Max 100 mm |

|

Coil outer diameter |

0 ~ 120 mm |

|

Coil width |

1/2 HP DC1Φ |

|

Motor |

1/2 HP DC1Φ |

|

Machine dimensions |

58 x 55 x 45 cm |

58 x 55 x 50 cm |

|

Weight |

43 kgs |

56 kgs |

|

|

|

Programmable

Automatic Coil Winding Machine (1 axis) Programmable

Automatic Coil Winding Machine (1 axis)

Programmable

Automatic

Coil

Winding Machine (2 axis) Programmable

Automatic

Coil

Winding Machine (2 axis)

Programmable

Automatic

Coil

Winding Machine (4 axis) Programmable

Automatic

Coil

Winding Machine (4 axis) |

|

|

|

Programmable Automatic Coil Winding Machine ( Thick Wire )

|

|

|

|

PHT-MH810A is designed for thick wire winding. It features

microcomputer control for easy operation and fast parameter setup,

ideal for high-torque, stable winding tasks. |

|

|

|

Model |

PHT- MH810A |

|

Spindle speed |

Max 500 RPM |

|

Wire diameter |

Max 4.0 Φ |

|

Coil outer diameter |

Max 250 Φ |

|

Coil width |

Max 180 mm |

|

Motor |

1 HP AC motor 3:1 reducer |

|

Machine dimensions |

650(L) x 400(W) x 600(H) mm |

|

Weight |

80 kgs |

|

|

|

Programmable

Automatic

Coil

Winding Machine Programmable

Automatic

Coil

Winding Machine |

|

|

|

Automatic Alignment Winding Machine |

|

|

|

This machine is suitable for electromagnets and other coil winding

without bobbins. It supports round wire and features automatic wire

alignment for neat and efficient winding. |

|

|

|

|

|

Model |

M927G2D |

|

Number of

spindles |

2 |

|

Wire

diameter |

0.1 Φ ~ 1.0 Φ |

|

Coil

outer diameter |

Max 100 Φ |

|

Speed |

6000 RPM |

|

Coil

width |

100 mm Max |

|

Motor |

1/2HP DC |

|

Power |

AC 110V/220V |

|

Machine

dimensions |

(L) 58 x (W) 52 x (H) 120 cm |

|

Weight |

48 kgs |

|

|

|

Automatic

Alignment Winding Machine Automatic

Alignment Winding Machine |

|

|

|

Designed for machine tool coils, this winding machine handles round

wire and features automatic wire alignment for neat and efficient

winding.

|

|

|

|

|

|

Model |

M927G1D |

|

Number of spindles |

1 |

|

Control method |

Microcomputer control |

|

Memory capacity |

999 Segment winding information |

|

Spindle speed |

0 ~ 3000 R.P.M |

|

Wire diameter |

0.5 ~ 2.0 mm |

|

Coil outer diameter |

100 mm Max |

|

Coil width |

0 ~ 120 mm |

|

Motor |

1/2 HP DC1Φ |

|

Machine dimensions |

(H) 65 x (L) 58 x (W) 55 cm |

|

Weight |

53 kgs |

|

|

|

|

Automatic

Alignment Winding Machine (M927G1D) Automatic

Alignment Winding Machine (M927G1D)

|

|

|

|

Self Melted Enameled Wire

Winding Machine |

|

|

|

The M927G2B is designed for coil products without bobbins. It offers

stable performance, easy operation, and uses electric heating to

dissolve enameled wire for improved efficiency and quality.

|

|

|

|

|

|

Model |

M927G2B |

|

Number of spindles |

1 |

|

Spindle speed |

0 ~ 3000 RPM |

|

Wire diameter |

Max 1.0 Φ |

|

Coil outer diameter |

Max 100 Φ |

|

Coil width |

Max 120 mm |

|

Motor |

1/2 HP DC |

|

Power |

110V/220V. 50/60HZ |

|

Machine dimensions |

(H) 110 x (L) 62 x (W) 60 cm |

|

Weight |

65 kgs |

|

|

|

|

|

|

Digital High Torque

Parallel Winding Machine |

|

|

|

This machine is designed for copper and flat copper wire winding in

transformers up to 5KVA. It delivers high torque with precise wire

alignment and supports standalone operation with dedicated

equipment. The digital interface offers multi-set memory functions,

while the tailstock’s cylinder with rubber support prevents

deformation and is movable. It supports single or dual-wire winding,

with spindle speed controlled by an inverter for stable and

efficient operation. |

|

|

|

Model |

PHT- MH810 |

|

Number of spindles |

1 |

|

Wire diameter |

0.3 ~ 6.0 mm |

|

Spread pitch |

0 ~ 9.999 mm |

|

Coil width |

230 (max) |

|

Coil outer diameter |

280 (max) |

|

Speed |

500 RPM |

|

Motor |

1HP |

|

Spindle motor |

Stepping type |

|

Storage |

999 Sequences |

|

Power |

AC 110V / 220V 50/60HZ |

|

Machine

dimensions |

110 x 56 x 50 cm |

|

Weight |

110 kgs |

|

|

|

Digital

High Torque Parallel Winding Machine Digital

High Torque Parallel Winding Machine |

|

|

|

|

|

|

|

|