Bead

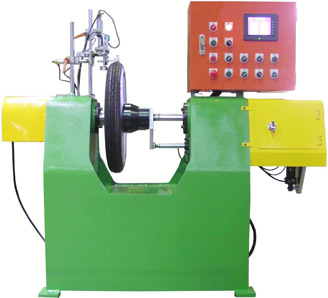

Wire Inner Circle Length Testing Machine | ¡@ | |

The bead wire inner circle length testing machine accurately measures

inner length, ensures consistent quality, and is easy to operate.

|

¡@ ¡@

¡@ ¡@ | Model | PHT - 76 | PHT - 77 | PHT - 78 | PHT - 79 | Wire size | 4¡¨ - 12¡¨ | 12¡¨ - 16¡¨ | 18¡¨ - 24¡¨ | 12¡¨ - 28¡¨ | Tire size | I/D, ATV, M/C | I/D, P/C, L/T, M/C | M/C, L/T, T/B | B/C | Accuracy | 0.1 mm | Control system | Micro touch screen | | Printer | 1 set | Air pressure | 3.5 kg / cm2 |

|

Tire

Wobble Testing Machine | ¡@ | |

The tire wobble testing machine checks tire runout and eccentricity,

improving driving stability and ensuring product quality.

¡@ | |  |

| |

Model | PHT - 1021 | PHT - 0510 | Tire size | M/C 10¡¨ - 21¡¨ | I/D, A/G 5¡¨ - 10¡¨ | Control system | Micro touch screen | Drum speed | 250 RPM / min | Motor | AC 2 HP ( Inverter ) | Air pressure | 6 kg / cm2 |

|

Tire

Endurance Testing Machine | ¡@ | |

The tire endurance testing machine simulates long-term driving to test

durability and safety, ensuring stable product quality.

|

¡@ ¡@ ¡@ ¡@ ¡@

¡@ ¡@

|

| ¡@Model | PHT - 821 | Tire size | S/C, M/C 8¡¨ - 21¡¨ | Test load | 100 - 1000 kgs | Test station | 2 positions | Test speed | 30 - 250 KM / hour | Road wheel | £X 1707.7 x 400 W | Motor | DC 75 HP | Speed setting | 24 steps speed / auto load control | Loading type | Hydraulic |

|

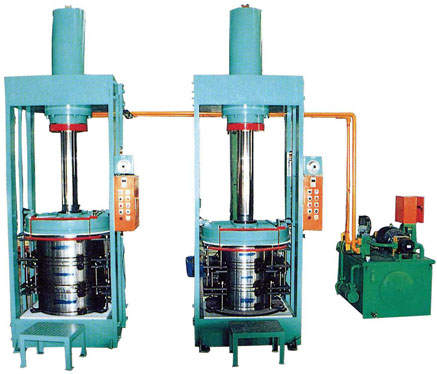

| 2 - Station

Flap

Curing Press

|

Flap Curing Press is a specialized machine used to heat and pressurize

tire flaps for vulcanization, helping them form correctly while

improving their elasticity, strength, and durability, with stable

control systems ensuring consistent product quality and production

efficiency.

¡@ |  |

Model | PHT - 1520 | Flap size | 15¡¨ ,16¡¨ , 20” | No. of daylight | 3 | Opening space | Max. 1,600 mm | Clamping force | Max. 148 tons | Hydraulic working pressure | 250 kg / cm2 | Steam pressure | 4 - 7 kg / cm2 | Pump motor | 10 HP |

|

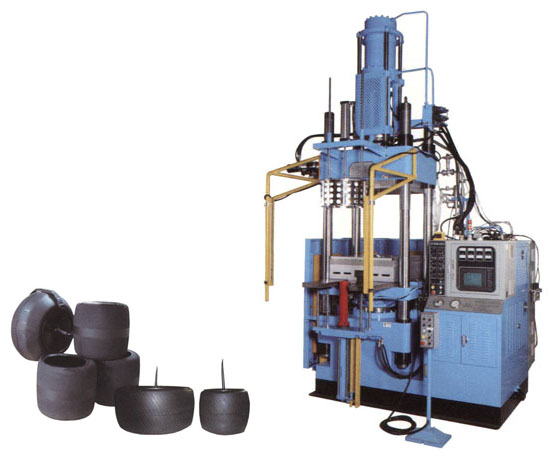

| ¡@ Tire

Bladder

Injection Molding Machine

The tire bladder injection molding machine significantly reduces

vulcanization time and enables the production of thinner bladders, cutting

material usage by 20¡V30% to lower costs. Compared to conventional

compression molding, bladder service life is extended by about 40%. Its

uniform wall thickness ensures consistent pressure, improving tire balance

and increasing the tire quality qualification rate by over 10%. | | ¡@ | | |  |

| Model | PHT - 400T | PHT- 800T | PHT- 1200T | PHT - 1500T | Injection unit : | Shot volume (cc) | 4000 |

7000 ~ 10000 |

10000 ~ 15000 |

15000 ~ 18000 | Injection pressure (kgf/cm ) ) | 1600 | 1300 ~ 1500 | 1200 ~ 1300 | Injection hydraulic pressure (Max)(Kg/cm ) ) | 150 | 150 ~ 160 | Charging unit : | Screw diameter (mm) | 45 | 65 | Screw speed (R.P.M.) | 0 ~ 120 | Material size (TxW)(mm) | 10 x 60 | 10 x 100 | Clamping unit : | Clamping force (ton) | 400 | 800 | 1200 | 1500 | Opening stroke (mm) | 650 | 1000 | Plate size (mm) | 900 x 900 | 1000 x 1000 | 1200 x 1200 | Piston diameter (mm) | 500 | 700 | 900 | 950 | Power | Motor (HP) | 40 | 50 | Heating source | Steam / Electric | Heating conduction motor ( K.W.) | 0.5 x 2 | System pressure ( kg/cm ) ) | 210 | Oil tank capacity ( liter ) | 600 | 950 | 1140 | General | Machine dimensions (cm) | 320x280x560 | 350x280x680 | 390x335x720 | 390x335x730 | Machine weight (Approx.) (kg) | 14500 | 23500 | 33000 | 37000 |

|

|