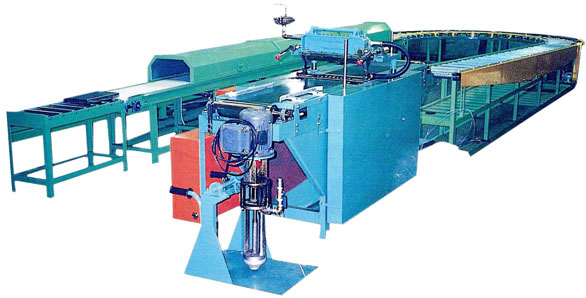

Tube

Valve Cement

Machine

The tube valve cement machine is used to apply adhesive to the rubber

base of tube valves.

It offers high-speed operation, excellent performance, simplified

processes, reduced labor, and consistent product quality.

|

Model |

PHT - 0400 |

|

Cementing part : |

Driving type |

Explosion proof motor 1 HP |

Speed control |

By frequency conveyor |

Conveyor type |

PVC non-joint belt |

Cementing width |

400 mm |

Coating conveyor motor |

1 HP |

Vehicle types |

All types |

|

Valve plate |

5 pcs (Size as customer required) |

|

Dry and conveyor part : |

|

Driving type |

Motor reducer x 2 HP |

|

Speed control |

By frequency conveyor |

|

Conveyor type |

Heat resistant rubber belt |

|

Dry length |

7200 mm |

|

Dry type |

Infrared ceramic electric heating 220V x 500 W x 20 sets |

Machine

type |

"U" type |

|

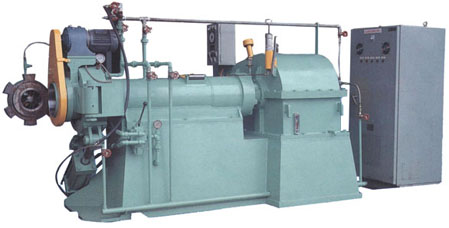

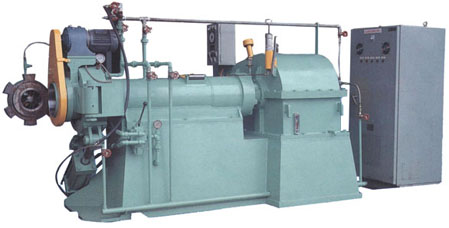

| °@ | | Strainer / Tube

Extruder | | °@ | |

The Strainer filters out impurities from raw materials to ensure

stable extrusion quality and extend equipment life.

The Tube Extruder melts and extrudes materials into hollow tubes,

serving as the core machine in tube production with heating, shaping,

and pressure control functions.

°@ |

| °@ °@ |

|

Strainer model

|

PHT - 120S |

PHT - 150S |

PHT - 200S |

|

Dia. of screw |

4 1/2°® |

6°® |

8°® |

|

Screw length |

20°® |

27" |

36" |

|

L/D ratio of screw |

4.5 : 1 |

|

Capacity ( kg/hr ) |

105 |

500 |

950 |

|

Motor ( AC HP ) |

40 |

75 |

100 |

°@

°@

°@

°@

°@

°@

°@ | °@

|

Tube extruder model

|

PHT - 120E |

PHT - 150E |

PHT - 200E |

|

Dia. of screw |

4 1/2°® |

6°® |

8°® |

|

Screw length |

27" |

36" |

48" |

|

L/D ratio of screw |

6 : 1 |

|

Capacity ( kg/hr ) |

105 |

350 |

850 |

|

Motor ( AC HP ) |

50 |

75 |

125 |

°@

°@

°@

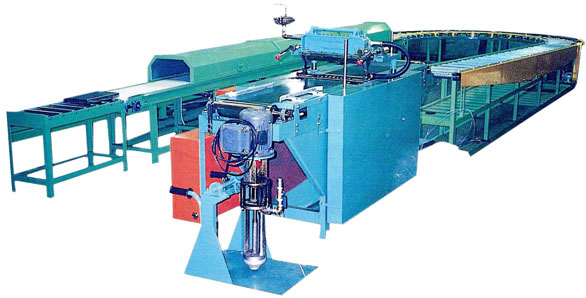

°@ | | °@ | | Tube

Extruding Conveyor Line | |

°@

The tube extruding conveyor line steadily transfers extruded tubes

to downstream processes, preventing deformation and improving

efficiency. It features automation, adjustable speed, and reliable

long-term operation.

|

Model | PHT - 3205 | PHT - 3805 | PHT - 5205 |

Tube size | M/C, B/C | M/C, S/C, I/D, P/S | Bus, Truck, L/T, P/S |

Tube cutting length (mm) | 720 - 2200 | 630 - 2200 | 630 - 2800 |

Apply range |

Both bent & straight valve |

Conveyor motor |

AC 5 HP ( Inverter ) |

Vacuum pump motor |

3 HP |

Conveyor height |

900 mm |

Conveyor speed |

5 - 25 m / min ( Adjustable ) |

Air pressure |

6 - 7 kg / cm |

|

Optional equipment : Dust collection system |

|

| °@ |

| °@ |

|

Spray Nozzle °@ |

|

The spray nozzle is designed for use in tube cooling machines and

other industrial cooling applications, providing efficient and

uniform spray distribution. |

|

|

°@ |

|

°@ |

| °@ °@ |

|

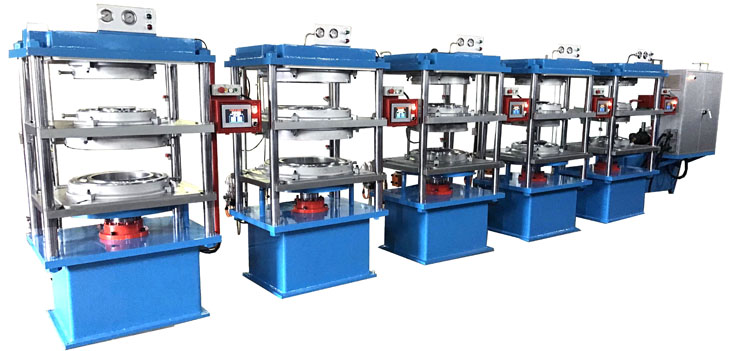

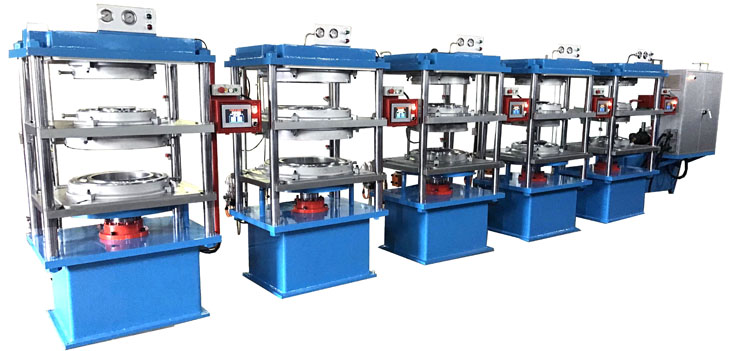

Tube

Curing Press |

|

°@

Tube Curing Press is a specialized machine used to heat and

pressurize rubber inner tubes for vulcanization, helping them form

properly while improving elasticity, air tightness, and durability,

with automatic control systems enhancing production efficiency and

product consistency.

°@ |

|

|

|

|

Model |

PHT - 85 |

PHT - 86 |

PHT - 87 |

|

Curing size |

7.50-15 ~ 12.00-20 |

6.00-13 ~ 8.25-16 |

B/C : °Ŕ20°®, M/C : °Ŕ12°®

P/S : 6.00-13 ~ 6.50-14 |

|

Mold O.D.

( mm ) |

£X

1195 |

£X

890 |

£X

785 |

|

Mold I.D.

( mm

) |

£X

380 |

Φ

255 |

Φ 100 |

|

Mold thickness

( mm

) |

320

~ 340 |

255

~ 280 |

170

~ 200 |

|

Steam pressure |

6 -

10 kg / cm2 |

|

Mold type |

Steam jacket heating mold |

|

Tube inflating |

Steam |

|

Air

pressure |

5 - 8 kg / cm2 |

|

Overall dimension ( mm) |

L2300

x W1700 x H1800 |

L1820

x W1260 x H1560 |

L1300

x W1080 x H1300 |

|

Mc weight |

3800

kgs |

2000

kgs |

1100

kgs |

°@

°@ |

|

°@

Hydraulic Type Tube Curing Press |

|

|

|

The hydraulic tube curing press provides stable high pressure for even

tube curing. It works with rubber or silicone materials and features

easy operation with automatic control of pressure and heating. It heats

quickly, maintains even temperature, and is durable, safe, and easy to

maintain°Xideal for long-term production.

°@ |

|

°@

Model |

PHT - 950 -150 |

Curing size |

M/C

tire |

Mold

O.D. |

Max

780 mm, Min 450 mm |

Mold

open space |

200

mm |

Fixed mold |

Use

T slot T screw |

Mold

type |

Steam jacket heating mold |

Internal pressure |

Air

& steam two stages |

Hydraulic cylinder |

£X

150 mm x 455st mm |

|

Max.

clamping force |

37

tons |

|

No.

of daylight |

2 |

|

Control system |

Human machine interfaces |

|

Operation |

Microprocessor touch screen |

|

Overall dimension |

L 1260 x W

1340 x H 1980 mm |

|

Machine weight |

1800

kgs |

|

|

°@ |

| Tube

Core Fitting Machine |

This high-performance machine is specifically designed for precise and

efficient installation. |

|

|

|

Model |

PHT - 9000 |

|

Apply range |

Core # 9000 |

|

Capacity |

B/C tube valve : 3 sec / pc

M/C tube valve : 4 sec / pc |

|

Air pressure |

6 kg / cm |

|

Overall dimension |

L 60 x W 50 x H 130 cm |

°@ |

|

|

°@ |

|

|

|