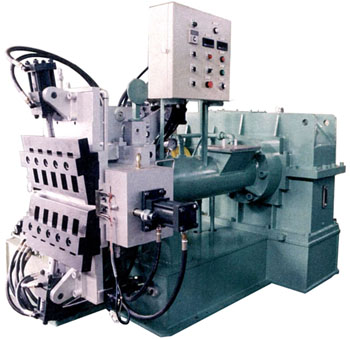

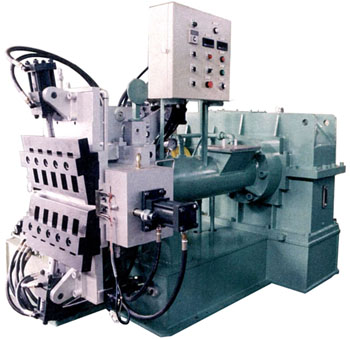

Hot

Feed Tread Extruder

This machine is a hot feed extruder equipped with a specially designed screw

and structure, making it ideal for processing hot feed materials. It is

specifically used for extruding rubber compounds for tire treads.

|

Model |

PHT - 120T |

PHT - 150T |

PHT - 200T |

|

Tire size |

B/C |

M/C, I/C |

ATV, L/T |

|

Dia. of screw |

4 1/2¡¨ |

6¡¨ |

8¡¨ |

|

Screw length |

27¡¨ |

36¡¨ |

48¡¨ |

|

L/D ratio of screw |

6 : 1 |

|

Capacity ( kg/hr ) |

300 - 500 |

600 - 900 |

900 - 1500 |

|

Motor ( DC HP ) |

50 |

75 |

150 |

¡@

|

|

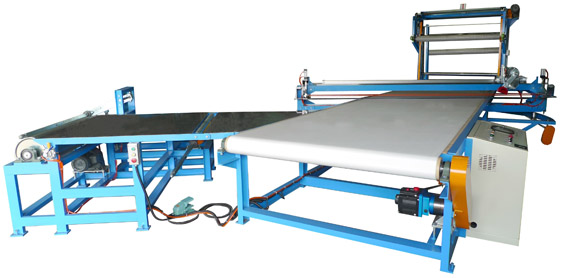

Bicycle

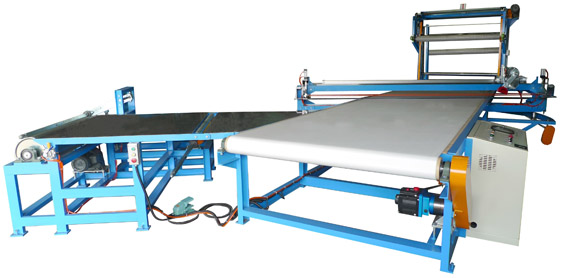

Tire Tread Cooling & Winding Conveyor

This machine is specially designed for cooling and winding tire treads. It

features high-performance cooling, a robust and reliable structure, and is

easy to maintain.

| ¡@

¡@ |

¡@

|

Model |

PHT - 310 |

|

Cooling drum |

£X 270 mm x L 730 mm x 12 pcs |

|

Driving motor |

AC 3 HP with inverter ( speed adjustable ) |

|

Line speed |

10 ~ 25 m / min

|

|

Tread winding unit |

6 units |

|

Cooling type |

Cooling water in/out with double rotary joint |

|

Driving mode |

Gear wheel and rack

|

|

Max winding diameter |

£X 500 mm |

|

Winder type |

Cylinder up and down operation |

|

Air cylinder |

£X 40 x 200 ST |

|

Wind up driver shaft |

32 mm ( square )

|

|

Compress air |

6 ~ 7 kg/cm |

|

Overall dimension |

L 7000 x W 1400 x H 1500 mm |

|

| | ¡@ | | ¡@ | Tread

Cooling Skiver Line |

This tread cooling and cutting machine can be adjusted according to

cutting requirements. The blades undergo special heat treatment for

durability and long-lasting sharpness, delivering clean and smooth cuts

that significantly enhance cutting efficiency and product quality. |

¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@

¡@ |

| | ¡@ |

|

Model |

PHT - 320 |

PHT - 340 |

|

Tire size |

I/D, M/C |

L/T, T/B |

|

Cutting speed |

20 pcs / min |

|

Conveyor speed |

2 - 25 m/min |

2 - 20 m/min |

|

Cutting thickness |

3 - 20 mm |

3 - 40 mm |

|

Tread width |

400 mm |

600 mm |

|

Cutting angel |

20 ~ 35¢X |

|

Total power |

35 HP |

|

Consist of : Pull out conveyor, water cooling conveyor, tread cutting & pick up conveyor. |

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@ |

Horizontal

Bias Cutter | ¡@ | |

The Horizontal Bias Cutter is used to precisely cut fabric or rubber

sheets at a set angle, commonly in tire production. It features

adjustable cutting angles, stable speed, and clean edges, enhancing

cutting accuracy and production efficiency. |

¡@ ¡@ ¡@ ¡@ ¡@ ¡@

¡@ ¡@ |

¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@

|

|

Model |

PHT - 142 |

PHT - 160 |

|

Tire size |

B/C, M/C, P/S, I/D, Bus & Truck tire |

|

Cutting angle |

38 - 85¢X |

|

Fabric width |

52¡¨ |

60¡¨ |

|

Cutting speed |

18 pcs / min for bicycle tire |

|

Cutting width |

80 mm ~ 1500 mm |

|

Bed width |

1700 mm |

|

Knife carrier |

Rodless cylinder |

|

Control system |

Micro touch screen |

|

Total power |

10 HP |

|

Air pressure |

5 - 7 kg / cm |

|

¡@ Horizontal

Bias Cutter with Return Type Splicing

This machine features bias cutting with return splicing,

enabling fast cutting and automatic joining of fabric or rubber

sheets, boosting efficiency and material usage in tire

production.

¡@ | |

|

|

| ¡@ |

|

|

|

¡@

Model | PHT - 160A | Tire size | B/C, M/C, P/S, I/D, Bus, Truck tire & Air spring | Cutting angle | 40¢X ~ 90¢X | Fabric width | 1500 mm | Belt width | 1600 mm | Cutting speed | 18 pcs / min for bicycle tire | Bead width | 1750 mm | Conveyor speed | 21 m / min | Cutting width | 80 mm ~ 1100 mm | Type of let off & wind up | 32 mm ¡¼ inner hole, Automatic type | Max. dia. of fabric | £X1000 mm | Control system | Micro touch screen | Total power | 10 HP | Knife carrier | Rodless cylinder | Angle of splicing table | Adjustable, 45¢X ~ 60¢X | Width of cut ply | Max. 600 mm | Liner cloth centering | By E.P.C | Air pressure | 5 ~ 7 kg / cm | Overall dimension | L 10530 x W 2980 x H 2130 mm |

¡@

¡@

¡@ |

Steel Metal Slitting Saw | | ¡@

High-speed steel (HSS) metal slitting saws are used in bias

cutting machines and similar applications. Various

specifications and sizes are available to meet different cutting

needs.

¡@ |

|

¡@

| Model |

PHT -

175 |

Material |

SKH - 9 |

Size |

100 x 1.0 x 25.4 £X x 36 T |

¡@

¡@

¡@

¡@

¡@ |

¡@

¡@ ¡@ |

Bead

Wire Grommet Machine ¡@

Specially designed for forming and fixing bead wire grommets. Ensures

precise positioning and strong bonding in tire manufacturing.

¡@

|  | | ¡@ | | ¡@ |

|

|

|

Model |

PHT - 61 |

PHT - 62 |

PUT - 63 |

|

Tire size |

B/C, M/C |

I/D, ATV, L/T, M/C |

I/D, ATV, L/T, T/B |

|

Forming size |

12¡¨ - 28¡¨ |

4¡¨ - 12¡¨ |

12¡¨ - 20¡¨ |

|

Production capacity |

10 - 20 pcs /min |

|

Total power |

14.5 HP |

|

No. of turns |

2 - 6 |

|

Cooling drum |

2 |

|

No. of reel |

6 |

|

Consist of : Auto ejector, festoon, stretch roll, rubber extruder, pre-heating stand, wire guide stand & reel stand. |

|