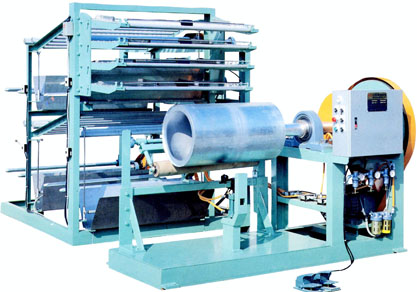

Tire building machine ( bladder turn up ) | PHT bladder type tire building machine are available in a wide variety of sizes from 8 to 21 inches. | ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@

|

| ¡@

Model |

PHT - 13 |

PHT - 21 |

PHT - 16 |

Tire size |

S/C, I/D

8¡¨ ~ 13” |

M/C

15¡¨ ~ 19¡¨, 17¡¨ ~ 21¡¨ |

L/T, P/S

13¡¨ ~ 16¡¨ |

Main shaft motor |

AC 3 HP |

AC 5 HP |

Under stitcher motor |

AC 1/2 HP |

AC 1 HP |

Ply servicer motor |

AC 1/2 HP |

Control system |

Automatic |

Air pressure |

5 - 7 kg / cm |

|

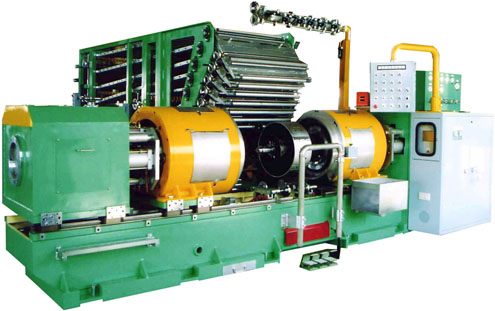

Band building machine with servicer

| The band building machine with servicer is designed to produce wide various sizes of tire from 8 to 20 inches. | | ¡@ ¡@ ¡@ ¡@ ¡@ ¡@

¡@ | ¡@

¡@ ¡@ |

Model |

PHT - 820 |

Tire size |

P/S, Bus, truck & light truck tire 8¡¨ ~ 20” |

Shaft speed |

30 / 180 RPM |

Fabric width |

Max. 1200 mm |

Main shaft motor |

AC 3 HP ( Inverter ) |

Control system |

Automatic |

Air pressure |

5 - 7 kg / cm |

|

|

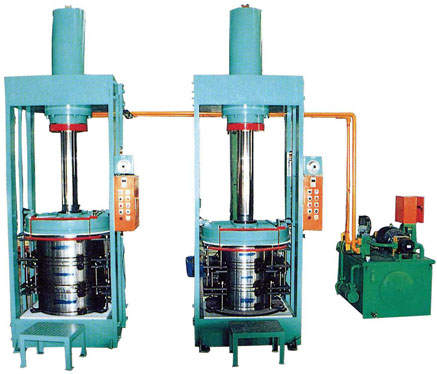

2 - Station flap curing press

|

Model |

PHT - 1520 |

Flap size |

15¡¨ ,16¡¨ , 20” |

No. of daylight |

3 |

Opening space |

Max. 1,600 mm |

Clamping force |

Max. 148 tons |

Hydraulic working pressure |

250 kg / cm |

Steam pressure |

4 - 7 kg / cm |

Pump motor |

10 HP |

|

|

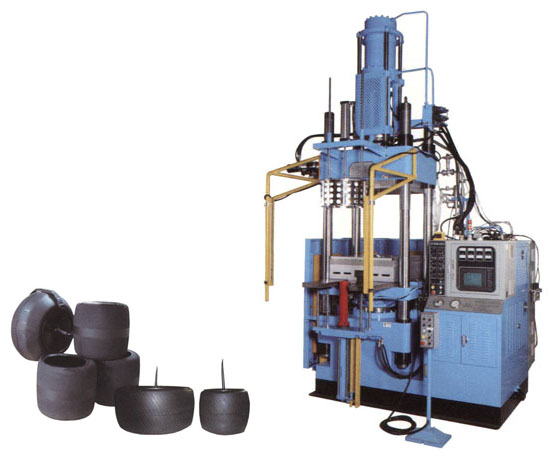

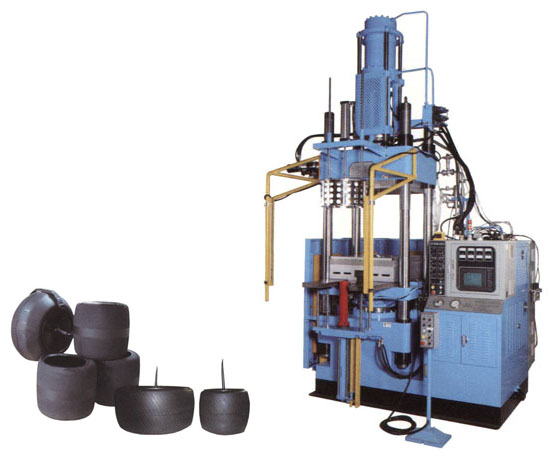

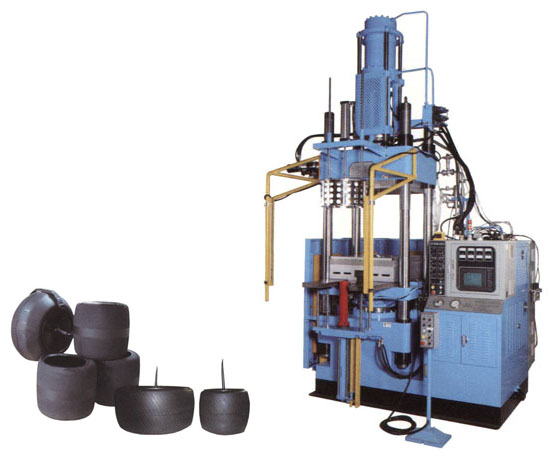

Tire bladder injection molding machine

Features :

Reduces vulcanization time to a minimum. Automatic material infeed without manual pre-forming. Thereby enormously shortening cycle time while upgrading efficiency. Shoots constant material according to cavity capacity. Capable of producing thinner bladder. Reduces material consumption by 20~30% for saving production cost. Bladder service life extended 40% over that produced by conventional compression molding method. Uniform and consistent bladder wall thickness provides uniform pressure on tires, assuring outstanding tire balance. Increases tire quality qualification percentage by over 10%. Efficiently saves energy consumption and labor requirement.

Machine construction : Injection system : The injection unit employs advanced, plunger-type injection. The screw provides material vulcanization and feeding functions to reduce time. Mold clamping system : Powerful clamping capacity with extra smooth motions. Fast mold clamping and opening

for enormously reducing cycle time. Integrated hydraulic circuit : The hydraulic circuit is an integrated design with a proportional flow and a pressure control valve, assuring superior operational performance. PLC controller : Equipped with an industrial grace PLC control combined with an over-sized touch-sensing

screen, providing the maximum operational convenience. Automatic temperature control : The heating platen is heated by steam while vulcanization and injection are heated by thermal oil. A heat exchanger provides automatic temperature control for vulcanization, assuring maximum stability and temperature uniformity.

|

|  |

¡@

|

Model |

PHT - 400T |

PHT- 800T |

PHT- 1200T |

PHT - 1500T |

Injection unit : |

Shot volume (cc) |

4000 |

7000 ~ 10000 |

10000 ~ 15000 |

15000 ~ 18000 |

Injection pressure (kgf/cm2) |

1600 |

1300 ~ 1500 |

1200 ~ 1300 |

Injection hydraulic pressure (Max)(Kg/cm2) |

150 |

150 ~ 160 |

Charging unit : |

Screw diameter (mm) |

45 |

65 |

Screw speed (R.P.M.) |

0 ~ 120 |

Material size (TxW)(mm) |

10 x 60 |

10 x 100 |

Clamping unit : |

Clamping force (ton) |

400 |

800 |

1200 |

1500 |

Opening stroke (mm) |

650 |

1000 |

Plate size (mm) |

900 x 900 |

1000 x 1000 |

1200 x 1200 |

Piston diameter (mm) |

500 |

700 |

900 |

950 |

Power |

Motor (HP) |

40 |

50 |

Heating source |

Steam / Electric |

Heating conduction motor ( K.W.) |

0.5 x 2 |

System pressure ( kg/cm2) |

210 |

Oil tank capacity (

liter ) |

600 |

950 |

1140 |

General |

Machine dimensions (cm) |

320x280x560 |

350x280x680 |

390x335x720 |

390x335x730 |

Machine weight (Approx.) (kg) |

14500 |

23500 |

33000 |

37000 |

|

|

|